ACT 3 – AIR CAPITAL TERMINAL 3

The new Wichita terminal is the gateway to the City of Wichita and as such it is the first and last impression for a large variety of visitors and residents to the City. The new terminal will emphasize Wichita’s perception as the “Air Capital of the World”, acknowledging the modern technology that keeps Wichita at the leading edge of the aircraft industry.

The City of Wichita and its Airport Authority began the process of considering the development of the third new airline terminal for Wichita back in the early 2000s. The first terminal was constructed in the early 1930s, and is now the home of the Kansas Aviation Museum. The existing terminal was the second airline facility for the community, and it was opened in 1954 when the McConnell Air Force Base opening forced the relocation of the City’s airport to the current site. Thus, the project to develop the newest terminal is called “Air Capital Terminal 3” or “ACT 3” to reflect the fact that this will be the third airline terminal for Wichita, the Air Capital of the World.

Timeline

Early 2000s – Airport Master Plan study was initiated. 20-year look into development opportunities and challenges.

2003 – Airport Master Plan study completed. Construction need to take place.

October 2004 – Wichita Airport Authority voted to move forward with the design of a new airline terminal to replace the 1954-vintage facility.

2005 – Program Management firm (AECOM Transportation) was selected and contracted to manage project for Airport Authority.

2006 – Master Architect/Engineer (HNTB Architecture) was selected and contracted to design the facilities.

Summer 2007 – Conceptual and Schematic Designs for the facility approved.

Late 2007 – FAA approves the Environmental Assessment for the project.

August 26, 2008 – The Design Development plans for the replacement airline passenger terminal were presented at City Hall.

2009 – Bidding for installation and development occurs.

September 13, 2012 – Ground breaking begins.

June 3, 2015 – The new terminal opens.

Terminal Features

- The building is designed to express flight and exemplify Wichita’s globally-prominent position in the aviation industry.

- The new state-of-the-art terminal has two levels and features 12 gates.

- A spacious ticketing wing is equipped with self-check in kiosks for a more efficient check-in process. Escalators, elevators, or stairs will take you to the second floor for security screening.

- The color scheme is based on the aircraft primer colors. This display shows many of the aircraft manufactured in Wichita.

- The iconic features of the ceiling elements located in the ticketing, baggage claim and concourse are meant to evoke the interiors of aircraft. The gentle bevel of the ceiling element is reminiscent of the window and surrounding casing on the interior of aircraft. In combination with ample daylighting, indirect lighting within the ceiling elements will softly fill the interiors with light.

- Twelve (12) boarding gates each equipped with a glass boarding bridge with pre-conditioned air and ground power for aircraft.

- Glass-walled jet bridges are made of the same structural framing of a regular jet bridge. The glass walls are 1-inch thick and made of tempered laminated insulated glass.

- The jet bridges can be raised or lowered to accommodate all aircraft (except small GA aircraft)

- Stairs and elevators are close to the main ticket lifts with easy access to the ramp for ground boarding operations

- 786 outlets and USB ports attached to new Arconas Flyaway seating for plugging in your mobile devices.

- Larger public restrooms with 59 stalls for women, 52 stalls for men, and 5 family restrooms.

- Expanded baggage claim area with three carousels

- Covered curbside and covered crosswalks to parking and rental cars

- Much larger TSA security checkpoint area

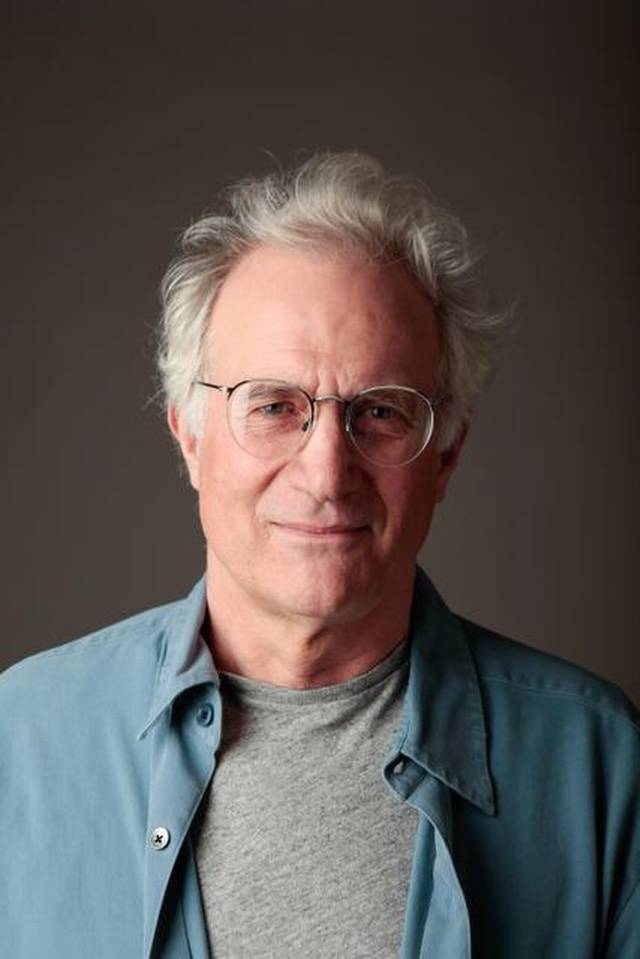

Ed Carpenter, Artist

Ed Carpenter is an artist specializing in large-scale public installations ranging from architectural sculpture to infrastructure design. Since 1973 he has completed scores of projects for public, corporate, and ecclesiastical clients. Working internationally from his studio in Portland, Oregon, Carpenter collaborates with a variety of expert consultants, sub-contractors, and studio assistants. He personally oversees every step of each commission, and installs them himself with a crew of long-time helpers, except in the case of the largest objects, such as bridges.

While an interest in light has been fundamental to virtually all of Carpenter’s work, he also embraces commissions that require new approaches and skills. This openness has led to increasing variety in his commissions and a wide range of sites and materials. His use of glass in new configurations, programmed artificial lighting, and unusual tension structures have broken new ground in architectural art. He is known as an eager and open-minded collaborator as well as technical innovator.

The main terminal sculpture is composed of cable and laminated dichroic glass mounted to the ceiling above the ticketing counters, baggage claim, and central mezzanine lobby areas. This sculpture is 360 feet in length and spans between columns under the skylights.

The art is meant to evoke images and feelings of flight and space as well as ascent and descent. Light from the skylights above will provide a continual changing color pattern on the walls and floor below.

Concessions

Concourse level, Post-Security: River City Brewery, Chick Fil’ A, Dunkin’ Donuts, Grab & Fly, Air Capital Bar, 3 CNBC Retail Shops

Main level Pre-Security: Aviator’s Café (restaurant, bar, shopping area in main terminal)

Sustainability Features

The ACT 3 Terminal is designed and constructed in accordance with Leadership in Energy and Environmental Design Guidelines.

Some sustainability attributes include:

- High performance building envelope including high R-factor insulation systems at walls and roofs and low solar heat gain glazing systems

- High performance HVAC systems, with sophisticated controls

- Use of groundwater for tempering baggage handling areas and heat for snowmelt systems at sidewalks

- Efficient lighting with controls that take advantage of daylighting from skylights and large glass walls to cut energy use further

- Recycling of construction waste materials

- Low water use plumbing fixtures

- Reduced solar heat impact through use of light colored paving and roofing

- Water efficient landscaping

- High performance building envelope with maximum insulation

- Efficient lighting with controls tied to natural daylight

- Bicycle racks for employees

- Use of regional materials to minimize transport

- Materials used to improve air quality and high efficiency air filtration

Fun Facts

- Square Footage – 275,000 SF, including 149,000 SF on Level 1, 118,000 SF on Level 2, and 6,000 SF in the basement

- Number of Gates – 12

- Number of Baggage Claims – 3

- Number of Ticket Counter Spots – 48

- Number of Security Lines – 4

- Number of Signs – 515

- Number of Escalators – 2

- Staircases – 12

- Number of Doors – 325

- Types of Finished Floors –Terrazzo, Tile, Stained Concrete and Carpet

- 1 3/8″ thick glass windows

- There are 7 unique types of windows on the exterior with different shades, colors, transparencies, and UV resistancies

- The walk from ticketing wing to your gate is 40-60% of the distance you used to walk.

Site/Structural Features

- Concrete Paving – 1,195,000 SF of new Aprons, Roads, and Sidewalks

- Concrete in the Building – 12,200 cubic yards

- Tonnage of Steel – 3,000 tons

- Exterior Walls – 112,000 SF of Masonry, Glass Curtain, and Composite Panels

Mechanical Features

- Radiant Floors – 23,000 SF

- Footage of Piping – 8.5 miles of Gas, Hydronic, and Water Lines

- Output of Chillers – 2,100 tons

- Number of Plumbing Fixtures – 267

Electrical/Communications

- Number of Light Fixtures – 970

- Number of Security Cameras – 143

- Length of new electrical and communication cabling – 114 miles

Cost

$160 million program, which includes enabling projects, design, management, building construction

Funding Sources

FAA Aviation Trust Fund (AIP) Grants (aviation users)

Transportation Security Administration Grants (aviation users)

Airport Passenger Facility Charges (PFCs)

Concessions

Parking

Rental Cars

Leases

Space Rental to Airlines

Airport system revenues

No local tax dollars are used

Contractors

AECOM – Program/Construction Management

HNTB Architecture – Architectural/Engineering Design

Key Construction/Walbridge – General Contractor

Design Team

HNTB Corporation Lead Architects, Kansas City

GLMV Architecture Associate Architects & Construction Administration, Wichita

Professional Engineering Consultants Civil, Electrical & Mechanical Engineering, Wichita

Dudley Williams & Associates Structural Engineering, Wichita

Greteman Group Public Art and Historical Element Design, Wichita

Landworks Studio Landscape Architect, Olathe, KS

FSC, Inc. Fire Protection Systems, Overland Park, KS

Ross & Baruzzini Communications & Technology, Webster Groves, MO

Logplan Baggage Handling Systems, Denver

Lightworks, Inc. Lighting Design, Weston, MO

Naughton& Associates, Inc. Signage & Graphics Design, Chicago

Ground-Breaking Ceremony September 13, 2012. Pictured: Jeff Longwell, Paul Gray, Victor White, Mayor Carl Brewer, LaVonta Williams, James Clendenin, Janet Miller

Award

The Wichita Dwight D. Eisenhower National Airport earned a Gold Award for the design of its new terminal at the 4th Annual Mid-America Design Awards presented by the International Interior Design Association. The award was presented on May 6, 2011 in Overland Park, Kan.

The new airport terminal —designed by HNTB Architecture, in association with GLMV Architecture —was recognized in the “Unbuilt” category. Critique was based upon innovation, implementation of design through use of materials, color, light and overall solution.

Features – Parking Garage

- 4 level, 1600 car parking garage designed for horizontal expansion

- Rental car service counters and lobby adjacent to the parking garage, plus covered rental car ready/return spaces

- Automated exiting

- More convenient express services and automated payment options

- Rental car pickup and drop-off on 1st level parking structure

- Rental car agency customer service center adjacent to garage

- Crosswalk canopies to provide a covered pedestrian path connecting with terminal

- Surface parking service offerings – Close-in, Economy and Park & Ride

Project Budget

$40 million general obligation bonds to be retired with airport revenues

Revenue Sources

- Customer Facility Charge (CFC)

- Rental car use and lease revenues

- Parking revenues

General Contractor

Crossland Construction

Design Team

Carl Walker, Inc., Parking Design Specialists, Dallas, TX

Schaefer Johnson Cox Frey, Architect & Landscape Architecture

Coover Clark

CONRAC Specialists, Denver, CO

Kent Williams, Aesthetic Enhancement Consultant

Ruggles & Bohm Civil Engineer

Midwest Engineering Mechanical Engineer

InSite Group Electrical Engineer

Bothner & Bradley Public Relations

Karagozian & Case Blast Risk Engineers

Terracon Geotechnical Engineer